Download Brochure ⬇

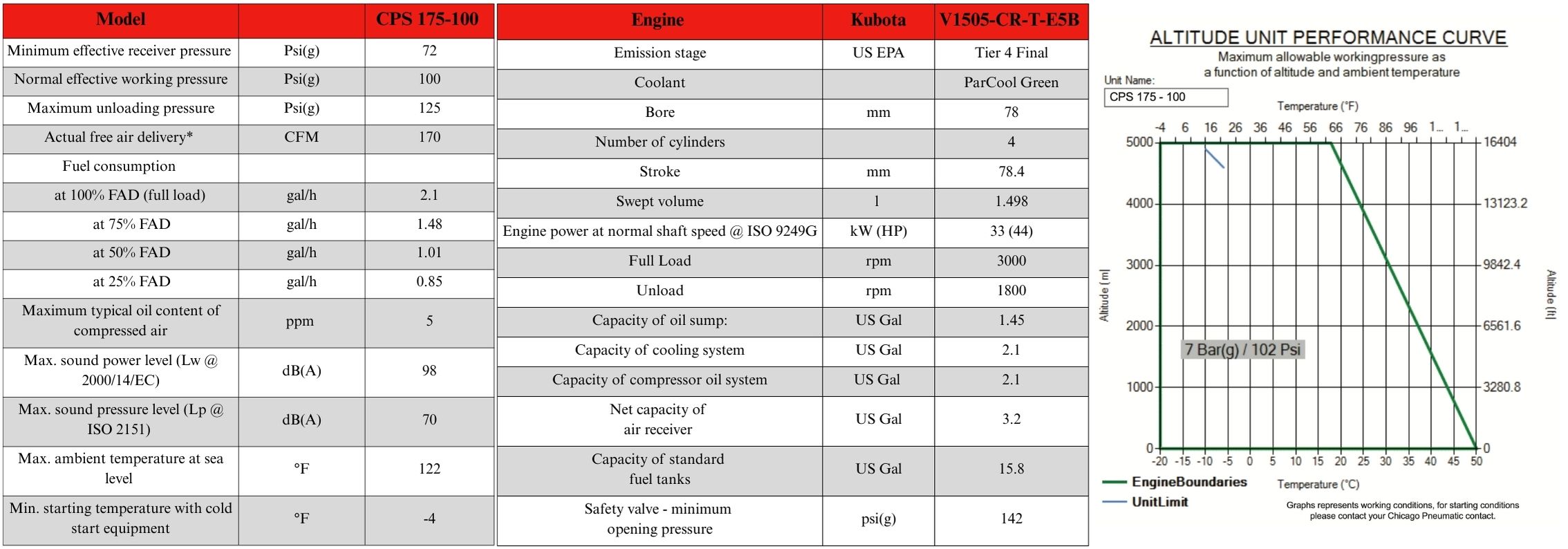

The Chicago Pneumatic CPS 175–100 is single-stage, oil-injected, rotary screw type air compressors, powered by a liquid- cooled, four-cylinder turbocharged Kubota diesel engine.

The unit hosts the new generation C67 Screw element in its air end combined with a Kubota made diesel engine model V1505-CR-T-E5B, complying with the T4F emission standard.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to ensure best in class cost of ownership.